Request For Quote

Request For Quote

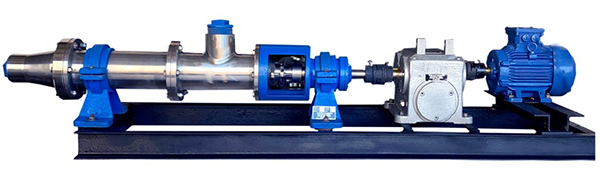

A progressive cavity screw pump with gear drive refers to a specific configuration of a progressive cavity pump that utilizes a gear mechanism for driving the rotation of the pump's screw-shaped rotor. This setup offers several advantages and features that enhance the pump's performance and functionality.

Here are some key aspects and benefits of a progressive cavity screw pump with gear drive:

1. Precision Control: Gear drives provide precise control over the rotational speed and torque of the pump's rotor, allowing for accurate adjustment of pumping parameters to match specific application requirements. This enables efficient handling of a wide range of fluids, including viscous liquids, slurries, and shear-sensitive materials.

2. High Efficiency: Gear drives offer high mechanical efficiency, minimizing energy losses during operation and maximizing the overall efficiency of the pumping system. This results in reduced energy consumption and lower operating costs over the pump's lifespan.

3. Smooth Operation: The gear drive mechanism ensures smooth and consistent rotation of the pump's rotor, resulting in a steady flow of fluid with minimal pulsations or fluctuations. This is particularly beneficial for applications requiring a constant flow rate or where gentle handling of the pumped material is necessary.

4. Compact Design: Progressive cavity screw pumps with gear drives typically feature a compact and space-saving design, making them suitable for installation in confined spaces or in mobile units. This allows for greater flexibility in pump placement and integration into existing process systems.

5. Durability and Reliability: Gear drives are known for their robust construction and reliable performance, providing long-term durability and minimal maintenance requirements. This ensures uninterrupted operation and reduces downtime, contributing to overall process efficiency and productivity.

6. Versatility: Progressive cavity screw pumps with gear drives are versatile and can be used in a wide range of applications across various industries, including oil and gas, wastewater treatment, food processing, mining, and chemical processing. They are capable of handling abrasive fluids, high-viscosity liquids, and fluids with high solids content.

7. Adaptability: Gear drives can be easily integrated with other system components, such as motors, couplings, and control systems, allowing for customization and adaptation to specific process requirements. This enables seamless integration into existing process lines or the design of new pumping systems tailored to the application needs.

Overall, a progressive cavity screw pump with gear drive offers efficient, reliable, and versatile pumping solutions for demanding industrial applications. By combining the benefits of progressive cavity pump technology with the precision and performance of gear drives, these pumps deliver consistent and dependable fluid transfer performance in diverse operating conditions.

Request For Quote